In the 1970s, there were no regulations governing emissions from wood or pellet stoves. However, with the introduction of EPA emission standards in 1988, stove manufacturers had to innovate to achieve cleaner burns. Their innovative solutions and commitment to environmental responsibility should inspire the audience.

While some stove manufacturers opted to use catalytic converters to burn smoke at lower temperatures, the majority focused on cleaner combustion through higher temperatures, typically above 1000°F. One widely adopted method was secondary combustion, which involves introducing warm air into a high-temperature zone of the stove. This process required redesigning the stoves to maintain enough heat for secondary combustion, leading to the development of baffle boards and blanket insulation.

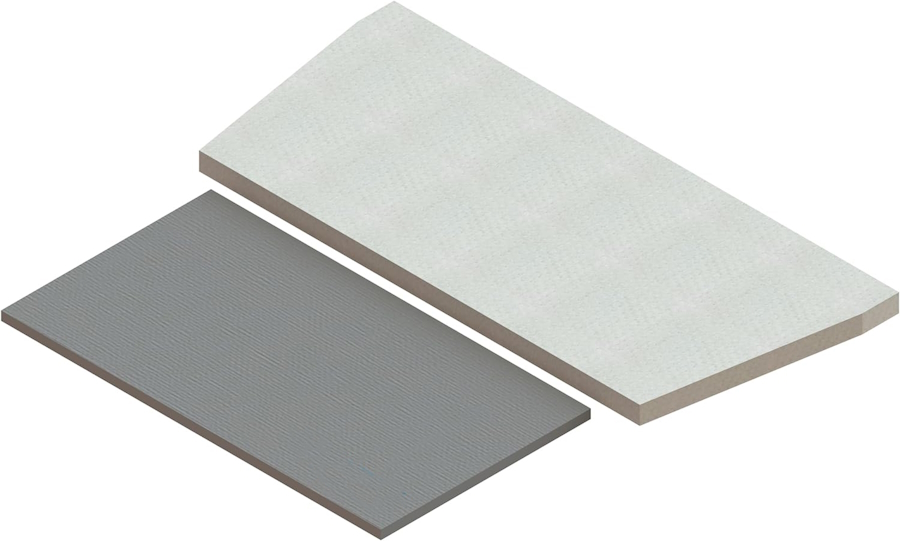

Initially, baffles were made from cast iron or hard firebrick. However, these materials didn't provide adequate insulation to reach the high temperatures necessary for a clean burn. Manufacturers then shifted to vermiculite-based fiber insulation boards, but these were later replaced by more efficient ceramic fiber insulating boards. Ceramic fiber boards offered better insulation and could withstand higher temperatures, up to 2300°F. Some stoves even used a combination of rigid ceramic fiber boards and soft ceramic fiber blankets to create areas hot enough to burn most smoke particulates.

Although ceramic fiber baffle boards excelled in passing EPA emission tests, they often failed in real-world conditions. Overloading stoves or using brushes during chimney cleaning frequently damaged these boards. To address this, many manufacturers began reinforcing ceramic fiber boards with coatings to improve durability.

Despite the success of ceramic fiber in helping stoves meet EPA standards, health concerns arose due to OSHA's Hazard Communication Standard (HCS) warnings about ceramic fibers. In response, many manufacturers transitioned to Superwool fiber for baffle boards. Superwool is a safer alternative, with low bio-persistence and no health warnings, and it provides slightly better insulation than ceramic fiber while maintaining a similar temperature limit. This transition marked a significant shift in the evolution of clean burn technology, as it not only addressed health concerns but also improved the efficiency and durability of wood stoves.

Recognizing the benefits of Superwool fiber for wood-burning appliances, Lynn Stove Parts played a significant role in the transition to Superwool insulation. They exclusively use Superwool for their baffle boards, demonstrating their commitment to safety and efficiency. Many of these boards are coated with a hard shell for added durability, making them stronger and more resilient than original manufacturer parts.

This combination of Superwool fiber and proprietary coating processes results in baffle boards that are more durable and reliable, offering superior performance in both emissions control and long-term stove use. This should instill confidence in the audience about the effectiveness of Superwool in wood-burning appliances.

/1003/site-assets/logo.png)