Exploring the World of Stove Mica Glass: Everything You Need to Know

An overview of stove mica glass, including its composition, uses, benefits, and cleaning instructions for wood stoves and heating appliances.

Overview of Stove Mica Glass

Stove mica glass, also known as mica stove glass, is pivotal in ensuring the efficient operation and safety of wood stoves and heating appliances. Made from natural mica, a mineral renowned for its heat-resistant properties, stove mica glass is essential due to its ability to withstand temperatures up to 1800 degrees Fahrenheit. This makes it an ideal material for use in environments where high heat is a constant factor, such as wood stoves and furnaces.

Historically, stove mica glass has been widely utilized in wood stoves, furnaces, and other high-heat devices to provide a transparent viewing panel. This allows users to monitor the combustion process and the condition of the burning materials inside the stove. Compared to ceramic glass, stove mica glass is preferred for its durability and resistance to thermal shock, making it a valuable choice for replacement panels in wood stoves.

The importance of stove mica glass cannot be overstated, as it not only ensures the visibility of the fire but also contributes to the overall safety and efficiency of wood stoves and heating appliances. Its unique properties and composition make it an indispensable material for maintaining heat and safety in these heating devices, thereby enhancing the user experience and longevity of the equipment.

What is Stove Mica Glass?

Stove mica glass, also known as mica stove glass, is essential in wood stoves and heating appliances. It is primarily made from natural mica, a resilient mineral from igneous and metamorphic rocks. This unique material is valued for its ability to withstand high temperatures, making it crucial for providing a clear view of the fire within wood stoves and heating appliances.

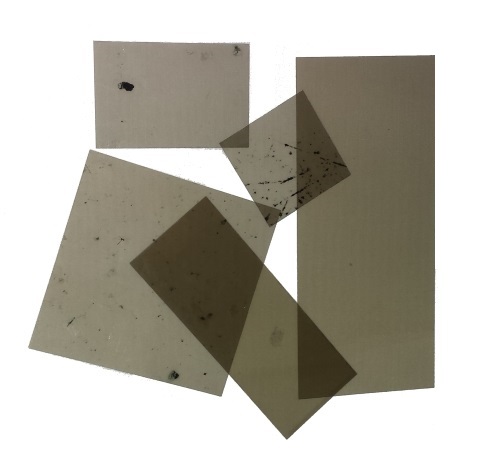

Mica, the primary component of stove mica glass, is a silicate mineral known for its exceptional thermal and electrical insulating properties. When mica is carefully processed into thin, translucent, and flexible sheets, it becomes an ideal material for withstanding the extreme heat generated in wood stoves, furnaces, and other high-heat devices. Stove mica glass can endure temperatures of up to 1800 degrees Fahrenheit, ensuring that it remains intact and functional even in the intense heat produced by these appliances. Additionally, its flexibility allows it to be cut to the specific size required for various heating appliances, making it a versatile and practical choice for replacement panels.

Compared to ceramic glass, stove mica glass has gained popularity due to its superior durability and resistance to thermal shock. While ceramic glass is also used in wood stoves, the ability of mica glass to withstand sudden temperature changes without cracking or shattering makes it a preferred option for ensuring the safety and longevity of heating appliances. This makes stove mica glass a practical choice and valuable for maintaining the heat and safety of wood stoves and other heating appliances.

Uses of Stove Mica Glass

Stove mica glass has a rich history of use in various heating appliances. For instance, in the 1700s, mica glass appeared in wood stoves and was also used in lanterns, furnaces, and boiler peepholes, demonstrating its versatility and high-temperature endurance. This long-standing tradition of incorporating mica glass into heating appliances reflects its reliability and effectiveness in providing a transparent and durable viewing panel for various devices.

Moreover, mica glass is often preferred over ceramic glass in wood stoves due to its exceptional durability and resistance to thermal shock. This makes it an ideal choice for homeowners looking for reliable, long-lasting materials to withstand the high temperatures generated in wood stoves and furnaces. The ability of stove mica glass to endure extreme heat while maintaining its structural integrity highlights its indispensability in ensuring the safety and functionality of heating appliances.

Benefits of Using Stove Mica Glass

Stove mica glass offers numerous benefits when used in wood stoves and heating appliances. Its durability and heat resistance make it an excellent choice for withstanding the high temperatures generated during the combustion process, ensuring the safety and longevity of the appliance. The ability of stove mica glass to withstand temperatures of up to 1800 degrees Fahrenheit makes it a reliable material for withstanding the extreme heat produced in wood stoves and other heating devices, contributing to its widespread use in such applications.

Furthermore, stove mica glass's thin, flexible, and translucent nature allows for effective heat insulation and provides a clear viewing panel for observing the fire or heating process. This translucency can enhance the aesthetic appeal of the wood stove, creating an ambiance of warmth and coziness in the living space. Additionally, the flexibility of mica glass allows for easy installation in various shapes and sizes, catering to the specific design requirements of different heating appliances. For instance, stove mica glass panels can be custom-cut to fit specific stove door sizes, providing a tailored solution for different wood stove models and designs.

In summary, the combination of durability, heat resistance, flexibility, and translucency makes stove mica glass a versatile and practical material for wood stoves and other heating appliances, contributing to enhanced safety, efficiency, and visual appeal in the heating process.

Cleaning and Maintenance of Stove Mica Glass

When cleaning and maintaining stove mica glass, it is essential to follow specific guidelines to ensure its longevity and effectiveness in wood stoves and heating appliances. To clean stove mica glass, a soft cloth, mild soap, and water are recommended to gently wipe away any dirt or residue that may have accumulated on the surface. It is crucial to avoid using abrasive materials or harsh chemicals, as they can cause damage to the glass and diminish its transparency over time. Using a gentle cleaning approach, stove mica glass can retain its clarity and functionality for an extended period.

In addition to cleaning, it is important to exercise caution when handling stove mica glass during maintenance activities. Avoiding contact with sharp objects is paramount, as any scratches or cuts can compromise the integrity of the glass. Furthermore, over-tightening hardware during cleaning and maintenance should be avoided to prevent any unnecessary stress on the glass, which could lead to breakage, especially when the unit is in use. By adhering to these maintenance practices, the stove mica glass can continue to serve its purpose effectively, providing a clear view of the fire and contributing to the overall safety of the heating appliance.

/1003/site-assets/logo.png)